There are two classifications of plastic materials, thermosets and thermoplastics. The classification is based on the chemical structure. Thermoplastics are made up of linear molecular chains whereas thermosetting plastics are made up of cross-linked molecular chains.

Thermoplastics

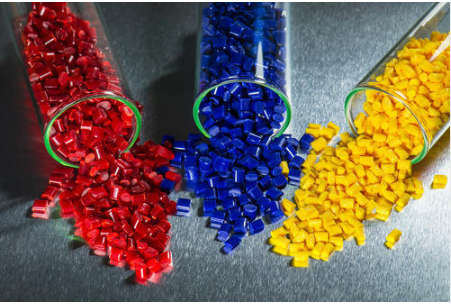

Thermoplastic commonly referred to as thermoplastic polymers are polymers that can be repeatedly heated and molded without effecting any change in their chemical or physical properties. Thermoplastics can be re-melted and re-shaped any number of times. They are usually stored in the form of pellets prior to the molding process.

Common Examples of Thermoplastics And Their Use

- Teflon: Used as lubricant for sliding doors and making machining parts such as gaskets.

- Polyvinyl Chloride: Used in making toys, pipes, cabinets and electrical insulators.

- Polypropylene: Used to make heat proof medical equipments and laboratory equipments.

- Acrylic: Used to make lightweight glass, eye lenses and battery covers.

- Polyethylene: Used to make gas tank coating, bullet resistant vests and movable machine parts.

- Nylon (Polymide): Used to make clothing, mechanical and automotive parts.

What You Need To Know About Thermoplastics

- A process of referred to as addition polymerization is used in the making of the thermoplastics.

- On heating, thermoplastics will soften and eventually melt.

- In solid state, their structure consists of hard crystalline regions together with elastic amorphous regions.

- Thermoplastics have weak, straight-chain bonds between them, a factor that makes them easy to be melted, re-melted and re-shaped a number of times.

- Thermoplastics are processed by injection molding, extrusion process, blow molding, thermoforming process and rotational molding.

- Thermoplastics have secondary bonds between molecular chains.

- Thermoplastic have a lower molecular weight when compared to thermosetting plastics.

- Thermoplastics have low melting points and low tensile strength.

- Thermoplastics are in the form of solid pellets before use.

- They are elastic and flexible in nature.

- They dissolve in organic solvents.

- Thermoplastics can be recycled or reformed.

Thermosetting Plastics

Thermosetting plastics also referred to as thermosets are plastics which remain in a permanent solid state after being molded and hardened, they cannot be reshaped or be recycled. Polymers within the material cross-link during the molding process to result into an unbreakable, irreversible bond. Thus, thermosets will not melt even when exposed to extremely high temperatures.

Common Examples of Thermosetting Plastics And Their Use

- Polyester Resins: Used to make bonding material, casting material and electrical components. It is also used to as body fillers in non-metallic cars.

- Bakelite: Used to make plastic ware, vehicle disc brake cylinders, plugs and sockets,

- Epoxy Resin: Used to make adhesives for automobiles, electronic components and in tooling jigs and fixtures.

- Urea–Formaldehyde: Used in making laminates, adhesive coatings, construction material and toilet items.

- Polyurethanes: Used to make print rollers, footwares, insulating forms and sealants.

What You Need To Know About Thermosetting Plastics

- A process referred to as condensation polymerization is used in the synthesis of thermosetting plastics.

- On heating, thermosetting plastics will char but never melt.

- When solid, their structure consists of the thermosetting resin interspersed with reinforcing fiber.

- Thermosets have strong chemical bonds between molecules, including cross-linking, which makes it difficult for them to melt when exposed to high temperatures.

- Thermosetting plastics are processed either through compression molding or reaction injection molding.

- Thermosetting plastics have primary bonds between molecular chains and held together by strong cross-links.

- Thermosetting plastics have a relatively higher molecular weight when compared to thermoplastics.

- Thermosetting plastics have a relatively higher melting points and tensile strength.

- Thermosets are in the liquid state before processing.

- Thermosetting plastics are hard and brittle in nature.

- They cannot dissolve in organic solvents.

- Neither can they be recycled or reformed.

Difference Between Thermoplastic And Thermosetting Plastic In Tabular Form

| BASIS OF COMPARISON | THERMOPLASTICS | THERMOSETTING PLASTICS |

| Processing | Addition polymerization is used in the making of the thermoplastics. | Condensation polymerization is used in the synthesis of thermosetting plastics. |

| On Heating | On heating, they soften and eventually melt. | On heating, they will char but never melt. |

| Solid State | In solid state, their structure consists of hard crystalline regions together with elastic amorphous regions. | When solid, their structure consists of the thermosetting resin interspersed with reinforcing fiber. |

| Chemical Bonds | They have weak, straight-chain bonds between them, a factor that makes them easy to be melted, re-melted and re-shaped a number of times. | They have strong chemical bonds between molecules, including cross-linking, which makes it difficult for them to melt when exposed to high temperatures. |

| Methods Of Processing | They are processed by injection molding, extrusion process, blow molding, thermoforming process and rotational molding. | They are processed either through compression molding or reaction injection molding. |

| Secondary Vs Primary Bonds | They have secondary bonds between molecular chains. | They have primary bonds between molecular chains and held together by strong cross-links. |

| Molecular Weight | They have a lower molecular weight when compared to thermosetting plastics. | They have a relatively higher molecular weight when compared to thermoplastics. |

| Melting Point & Tensile Strength | They have low melting points and low tensile strength. | They have a relatively higher melting points and tensile strength. |

| Physical State Before Use | They are in the form of solid pellets before use. | They are in the liquid state before processing. |

| Nature | They are elastic and flexible in nature. | They are hard and brittle in nature. |

| Dissolving In Organic Solvents | They dissolve in organic solvents. | They cannot dissolve in organic solvents. |

| Recycling | Neither can they be recycled or reformed. | Neither can they be recycled or reformed. |

Advantages And Disadvantages of Thermosetting Plastics & Thermoplastics

Advantages

Thermoplastics

- It easy to blend them with other thermoplastics.

- Highly resistant to corrosive chemicals.

- They can be recycled and be put to another use.

- They possess a high impact resistance.

- When used to make surfaces, they produce a fairly good surface finish.

Thermosetting Plastics

- They are highly durable.

- They possess a high resistance to both chemical and heat.

- They are rigid with lots of strength.

- When used to make surfaces, they produce a fairly good surface finish.

- They are flexible as they can adapt to any design process.

Disadvantages

Thermoplastics

- They are costly.

- They are heat and UV sensitive

- They experience structural deformation on long term load application.

Thermosetting Plastics

- They are not recyclable.

- They experience structural deformation when subjected to high force impact.

- In case of breakage, it’s difficult to repair.

- It is not possible to blend thermosets by welding.

- It is difficult to achieve a good surface finish when used.