Batch Fermentation (Batch Culture)

Batch fermentation is the simplest mode of fermentation; it is made up of a mechanically stirred vessel with other accessories such as a gas sparger and a heating/cooling jacket. It is also widely used in biological industry, including microbial fermentation, cell metabolism and production of products. In batch fermentation, substrate and microorganisms are loaded into the fermenter batchwise.

What You Need To Know About Batch Fermentation

- Fermentation is carried out in a closed fermenter, with nothing added or removed during the process (except venting of gas).

- The process is easy to set up and run. Instrumentation is not that complex.

- The fermenter has to be washed before the subsequent step of fermentation is undertaken.

- It is suitable for the production of secondary metabolites whose production is never associated with the growth of the microbes. Example includes antibiotics.

- Environmental conditions in the fementer are never kept constant.

- Contents of the fermenter are removed after the fermentation process for the isolation of products.

- Usually, nutrients in the fermenter are utilized at a relatively slow rate.

- Nutrients are added only once, at the beginning and never added in between the fermentation process.

- It is less suitable for the production of biomass such as Single Cell Proteins (SCP).

- Microbes in the fermenter show lag, log and stationary growth phases.

- The process is comes to an end once the product is formed.

- Batch fermentation has a huge application in industrial production.

- The conversion of the substance into desired product is less (Turnover is less).

- The fermenter can be used for different reactions with each separate use.

- Batch fermentation results in a significant periods of time between use, this eventually results in higher costs.

Continuous Fermentation (continuous Culture)

Continuous fermentation is an open system whereby sterile substrate is added to the system at a specific dilution rate while an equal volume of converted substrate containing the product together with the producer is simultaneously removed. The advantages claimed for continuous fermentation include efficient plant utilization, improved carbohydrate utilization, increased throughput and consistency.

What You Need To Know About Continuous Fermentation

- Fermentation is carried out in an open fermenter , with nutrients added and product removed at steady rate throughout the entire process.

- The process is not that easy to setup. It requires some sophistication in terms of instrumentation.

- The fermenter is never washed before the subsequent step of fermentation because there is continuous addition of nutrients and microbes.

- It is suitable for the production of primary metabolites whose production is associated with the growth of the organism. Examples include organic acids and amino acids.

- Environmental conditions in the fermenter will always be kept constant.

- Contents of the fermenter are never removed for the isolation of products, as they extracted from the overflow from the fermenter.

- Usually, nutrients in the fermenter are utilized at a relatively faster rate.

- Nutrients are added many times at the beginning and in between the fermentation process.

- It is more efficient and suitable for the production of biomass such as Single Cell Proteins (SCP).

- Optimum or exponential growth rate of microbes is maintained in the fermenter.

- The process does not come to an end for the collection of the product once the product is formed, but the product is continuously taken out from the fermenter.

- Continuous fermentation has a limited application in industrial production.

- The conversion of the substance into desired product is high (Turnover is high).

- There is high risk of contamination due to constant adjustments.

- Continuous fermentation entails a continuous reaction with no idle time, reducing labor costs and increasing product yields.

Difference Between Batch And Continuous Fermentation In Tabular Form

| BASIS OF COMPARISON | BATCH FERMENTATION | CONTINUOUS FERMENTATION |

| Description | Fermentation is carried out in a closed fermenter, with nothing added or removed during the process (except venting of gas). | Fermentation is carried out in an open fermenter , with nutrients added and product removed at steady rate throughout the entire process. |

| Flexibility | The process is easy to set up and run. Instrumentation is not that complex. | The process is not that easy to setup. It requires some sophistication in terms of instrumentation. |

| Washing Of The Fermenter | The fermenter has to be washed before the subsequent step of fermentation is undertaken. | The fermenter is never washed before the subsequent step of fermentation because there is continuous addition of nutrients and microbes. |

| Suitability | It is suitable for the production of secondary metabolites whose production is never associated with the growth of the microbes. Example includes antibiotics. | It is suitable for the production of primary metabolites whose production is associated with the growth of the organism. Examples include organic acids and amino acids. |

| Environmental Conditions | Environmental conditions in the fementer are never kept constant. | Environmental conditions in the fermenter will always be kept constant. |

| Isolation Of Products | Contents of the fermenter are removed after the fermentation process for the isolation of products. | Contents of the fermenter are never removed for the isolation of products, as they extracted from the overflow from the fermenter. |

| Rate Of Nutrient Utilization | Usually, nutrients in the fermenter are utilized at a relatively slow rate. | Usually, nutrients in the fermenter are utilized at a relatively faster rate. |

| Nutrients Addition | Nutrients are added only once, at the beginning and never added in between the fermentation process. | Nutrients are added many times at the beginning and in between the fermentation process. |

| Suitability In Production Of Biomass | It is less suitable for the production of biomass such as Single Cell Proteins (SCP). | It is more efficient and suitable for the production of biomass such as Single Cell Proteins (SCP). |

| Growth Rate Of Microbes | Microbes in the fermenter show lag, log and stationary growth phases. | Optimum or exponential growth rate of microbes is maintained in the fermenter. |

| End Of Process | The process is comes to an end once the product is formed. | The process does not come to an end for the collection of the product once the product is formed, but the product is continuously taken out from the fermenter. |

| Application | Batch fermentation has a huge application in industrial production. | Continuous fermentation has a limited application in industrial production. |

| Turnover | The conversion of the substance into desired product is less (Turnover is less). | The conversion of the substance into desired product is high (Turnover is high). |

| Contamination Risk | The fermenter can be used for different reactions with each separate use. | There is high risk of contamination due to constant adjustments. |

| Costs | Batch fermentation results in a significant periods of time between use, this eventually results in higher costs. | Continuous fermentation entails a continuous reaction with no idle time, reducing labor costs and increasing product yields. |

What Are Some Of The Similarities Between Batch Fermentation And Continuous Fermentation

- Both processes take place under controlled environmental conditions.

- Both processes can be used for the production of microbial biomass.

- The mechanical engineering and components of fermenters in both case is almost similar.

- Both are large scale industrial production processes.

- Batch and continuous fermentation can be used for the production of dairy starter cultures.

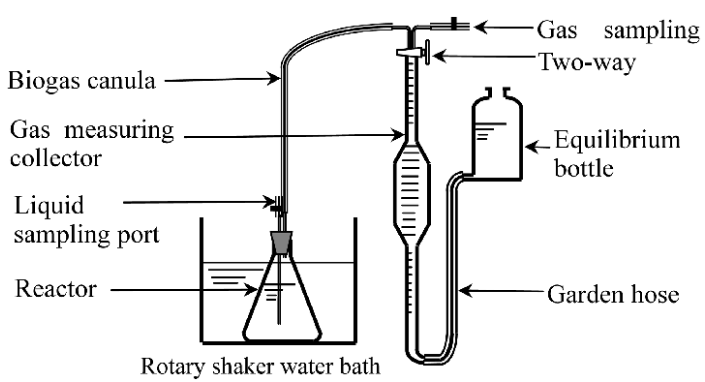

Batch Culture Diagram

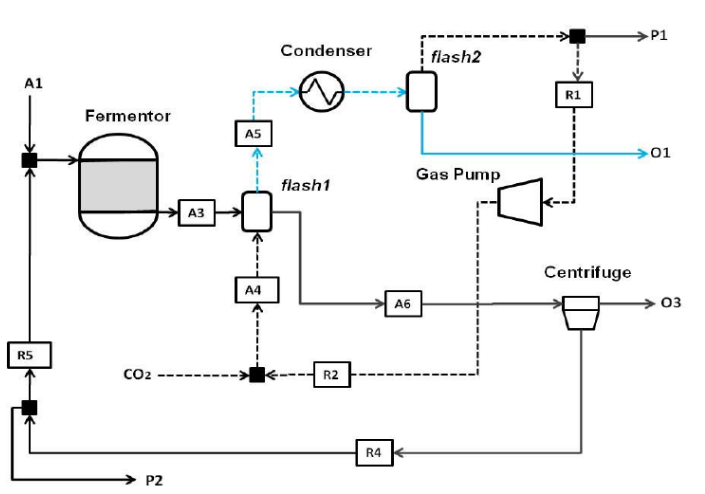

Continuous Fermentation Diagram