An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit.

Internal Combustion Engines can be classified into:

- Gasoline Engines, which are commonly used in cars, motorcycles, lawnmowers, and small power equipment. They burn gasoline to produce mechanical energy.

- Diesel Engines, commonly found in cars, trucks, buses, ships, and industrial machinery. Diesel engines use compression ignition and run on diesel fuel.

- Natural Gas Engines, which operate on natural gas and are often used in power generation, transportation, and industrial applications.

- Dual-Fuel Engines which can run on two different fuels, such as diesel and natural gas.

Internal combustion engines can further be described as 2-stroke or 4-stroke in nature. They are called “2-stroke” and “4-stroke” based on the number of strokes required to complete one full operating cycle. A stroke refers to the movement of the piston inside the engine cylinder. Let us look at the major difference between 2-stroke and 4-stroke engines based on their operating principles, mechanics, applications and trade-offs.

What is a 2 Stroke Engine?

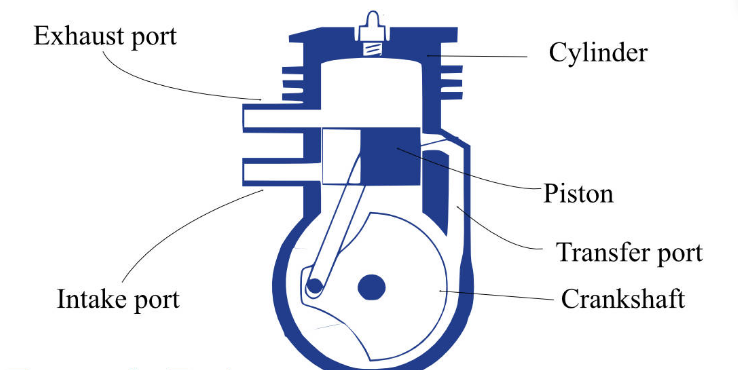

A 2-stroke engine is a type of internal combustion engine that completes one full operating cycle in just two strokes of the piston. This engine is usually a simpler design when compared to the more common 4-stroke engine that has more moving parts. The two strokes of this engine are:

Intake and Compression (First Stroke):

- The first stroke is known as the intake and compression stroke. The piston moves downward, creating a vacuum in the cylinder.

- As the piston moves down, the crankcase below the piston becomes pressurized with a mixture of air and fuel.

- The air-fuel mixture enters the crankcase through ports or reed valves located on the sides of the cylinder.

Combustion and Exhaust (Second Stroke):

- The second stroke is known as the combustion and exhaust stroke. As the piston reaches the bottom of its stroke, it starts moving upward.

- As the piston moves up, it compresses the air-fuel mixture in the crankcase. The compressed mixture is forced upwards through transfer ports or passages into the combustion chamber above the piston.

- At the top of the stroke, the air-fuel mixture is ignited by a spark plug.

- The ignition causes a rapid combustion and expansion of gases, generating a high-pressure force that drives the piston downward with significant power.

- As the piston reaches the bottom of its stroke again, it uncovers the exhaust ports, and the burnt gases are expelled from the cylinder.

The cycle then repeats with the next downward movement of the piston, starting with the intake and compression stroke.

Applications of 2-stroke engines

- Chainsaws and other handheld power tools

- Small motorcycles and scooters

- Marine outboard engines for boats

- Some low-power recreational vehicles

- Lawnmowers and other garden equipment

- Portable generators

What is a 4 Stroke Engine?

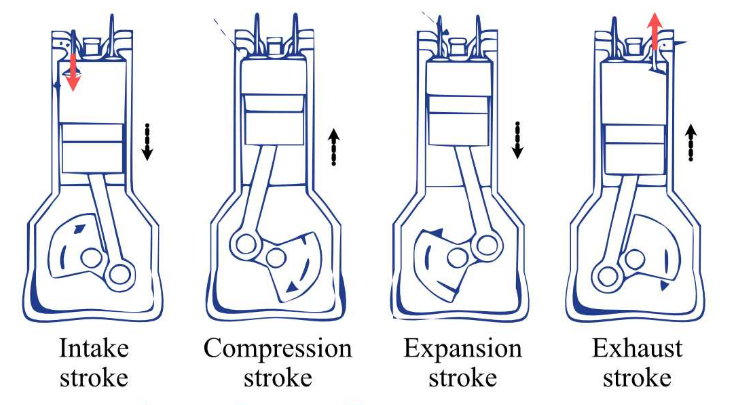

A 4-stroke engine is a type of internal combustion engine that completes one full operating cycle in four strokes of the piston. It is the most common type of engine used in automobiles, motorcycles, trucks, buses and many industrial applications. 4-stroke engines have smoother operation compared to 2-stroke engines. The four strokes of this engine are:

Intake Stroke (First Stroke):

- During this stroke, the piston moves downward from the top dead center (TDC) to the bottom dead center (BDC).

- As the piston moves down, the intake valve opens, and the cylinder draws in a fresh mixture of air and fuel from the intake manifold.

- The downward movement of the piston creates a vacuum in the cylinder, helping to draw the air-fuel mixture into the combustion chamber.

Compression Stroke (Second Stroke):

- The second stroke is known as the compression stroke. The piston moves upward from BDC to TDC.

- Both the intake and exhaust valves are closed during this stroke, sealing the combustion chamber.

- As the piston moves up, it compresses the air-fuel mixture, leading to a significant increase in pressure and temperature.

- At the end of the compression stroke, the air-fuel mixture is highly compressed and ready for combustion.

Power Stroke (Third Stroke):

- During this stroke, the piston moves downward from TDC to BDC.

- Near the end of the compression stroke, a spark plug ignites the compressed air-fuel mixture in the combustion chamber.

- The ignition causes a rapid combustion and expansion of gases, creating a high-pressure force that drives the piston downward with significant power.

- This downward motion of the piston is what generates the mechanical work required to turn the engine’s crankshaft.

Exhaust Stroke (Fourth Stroke):

- During the exhaust stroke, the piston moves upward from BDC to TDC.

- As the piston moves up, the exhaust valve opens, and the burnt gases from the power stroke are expelled from the cylinder into the exhaust manifold.

- The exhaust gases are then directed out of the engine through the exhaust system.

The cycle then repeats, starting with the intake stroke, and the engine continues to operate in a continuous cycle as long as there is a supply of air-fuel mixture and a source of ignition (spark plug).

Also Read: Difference Between Otto cycle And Diesel Cycle

Applications of 4-stroke engines

- Passenger cars and commercial vehicles

- Motorcycles, including both street and off-road models

- Trucks, buses, and other heavy-duty vehicles

- Industrial machinery and equipment

- Power generators and pumps

- Marine Engines

- Agricultural Equipment

Read Further: Difference between Diesel and Petrol Engine

2-Stroke Engine Vs. 4-Stroke Engine In Tabular Form

| Basis | 2–Stroke Engine | 4-Stroke Engine |

| Power Production | The 2 stroke engine produces power once every 2 strokes of the piston. It usually generates high torque. | The 4 stroke engine takes 4 strokes to produce the power and usually generates less torque for its 2 strokes cycle. |

| Flywheel | Require lighter flywheel compare to other engines because it generates more balance force due to one revolution for one power stroke. | Requires heavy flywheel because it generates unbalanced force due to two revolutions for one power stroke. |

| Burning Of The Charge | The charge is partially burn and mix with the burn gases during inlet due to port mechanism. | The charge is fully burn and does not mix with burn charge in ideal condition. |

| Efficiency | Two stroke engines are less efficient and produce more smoke. | 4 stroke engines are more efficient and produce less smoke. |

| Working Of The Piston | When the piston goes for the cylinder on top position, it forces the spark to ignite air and when it explodes, it drives the piston downwards. | When the piston is in the top position to the cylinder, the spark plug burns the air (fuel) and brings the piston down onto the power-stroke and makes the valve close. |

| Weight | Two stroke engines are comparatively lighter than 4 stroke engines. | Four stroke engines are comparatively heavier than 2 stroke engines due to heavy flywheel and valve mechanism. |

| Lubrication | 2 stroke engines requires comparatively more lubricating oil than 4 strokes engines because some oil burn with fuel. | 4-stroke engines require comparatively less lubricating oil than 2 stroke engine. |

| Thermal Efficiency | Give less thermal efficiency when compared to 4 stroke engines that give more thermal efficiency. | Give more thermal efficiency when compared to 2 stroke engines that give less thermal efficiency |

| Wear & Tear | Need regular lubrication because of more wear and tear problem that exist in this type of engine. | Have a complex lubrication system and hence cases of wear and tear are way less. |

| Use | Commonly used in ships, motorcycles, scooter, snowmobiles etc . | Commonly used in road vehicles like trucks, cars and other related automobiles. |

| Engine Design | Engine design is such that there are 2 ports for fuel to get in and out. This design makes its mechanism simpler. | Engine design is a bit complicated due to the valve that is operated through a chain and gear mechanism. |

| Affordability | Two stroke engines are comparatively cheaper and affordable to 4 stroke engines. | Four stroke engines are comparatively expensive and less affordable to two stroke engines. |

Also Read: Difference Between Carnot Cycle And Renkine Cycle

Advantages And Disadvantages of Four-Stroke Engines

Advantages

- Four-stroke engines yield higher levels of torque at a lower RPM during operation.

- A four-stroke engine only consumes fuel once every four strokes, making it a more fuel-efficient engine option.

- Four-stroke engines give off less pollution because they do not require oil or lubricant mixed in the fuel.

- These engines are durable and can withstand higher amounts of wear and tear.

- You will not need additional oil with a four-stroke engine.

- A four-stroke engine produces less noise and vibration during operation.

Disadvantages

- The additional components in the four-stroke design make these engines heavier compared to the two-stroke version.

- A four-stroke engine contains more parts and valves, making repairs and maintenance more expensive.

- Since it only receives power once every four rotations of the piston, this design is less powerful than a comparable two-stroke engine.

- This engine design features a gear and chain mechanism, which can cause complications during maintenance.

- A four-stroke engine requires regular maintenance, leading to an increase in costs for products and services.

Advantages And Disadvantages of Two-Stroke Engines

Advantages

- A two-stroke engine weighs less compared to a four-stroke engine and requires less space.

- The engine’s turning movement is even since it takes one power stroke for each crankshaft revolution.

- This engine’s design is simple due to the lack of a valve mechanism.

- During operation, this engine creates less friction on parts and has increased mechanical efficiency.

- This engine features a significant power boost with a high power-to-weight ratio.

- The engine can operate at cold and hot external temperatures.

- The engine has inlet and exhaust ports.

Disadvantages

- Two-stroke engines consume more fuel, and only a small amount of fresh charges mix with gasses from the exhaust.

- You may experience a high amount of vibration or noise during operation.

- This engine has a shorter life span since it incurs increased wear and tear.

- A two-stroke engine has a narrow power band, or range of speed where the engine is most efficient.

- This engine type may become unstable while idling.

- You may experience issues with scavenging with this engine.

- A two-stroke engine does not burn as cleanly, leading to a higher level of air pollution than a four-stroke engine.

Key Takeaway

In a 2-stroke engine, one full operating cycle is completed in just two strokes of the piston. The two strokes are: a) Compression stroke: The piston moves upward, compressing the air-fuel mixture in the crankcase. b) Combustion/exhaust stroke: When the piston reaches the top of its stroke, the spark plug ignites the compressed mixture, causing a rapid expansion of gases that pushes the piston downward. At the same time, the exhaust gases are expelled from the cylinder.

In a 4-stroke engine, one full operating cycle is completed in four strokes of the piston. The four strokes are: a) Intake stroke: The piston moves downward, and the intake valve opens, allowing a mixture of air and fuel to enter the cylinder. b) Compression stroke: The intake valve closes, and the piston moves upward, compressing the air-fuel mixture. c) Power stroke: The compressed mixture is ignited by a spark plug, causing an explosion and driving the piston downward. d) Exhaust stroke: As the piston moves upward again, the exhaust valve opens, and the spent gases are expelled from the cylinder.

Comments are closed.