When it comes to electromechanical systems, electric motors are generally used to convert electrical energy into mechanical energy. Among the various types of electric motors, the 2 pole and 4 pole motors stand as the most common. Let us talk about 2 pole vs 4 pole motors by looking at the principles behind their operation, the design distinctions that render them unique and the diverse domains where they find their ideal applications.

2 Pole And 4 Pole Motors

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor’s magnetic field and electric current in a wire winding to generate force in the form of rotation of a shaft. Electric motors may be classified by considerations such as power source type, internal construction, application and type of motion output.

The number of poles is the factor that determines the synchronous speed of an induction motor. In other words, the number of poles reflects the synchronous speed of the motor. The 2-pole synchronous speed is 3000r/min, the 4-pole synchronous speed is 1500r/min, the 6-pole synchronous speed is 1000r/min, and the 8-pole synchronous speed is 750r/min.

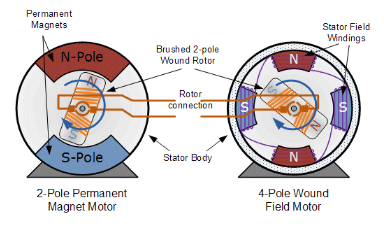

As the name implies, a 2-pole motor has 2 electromagnets; 1 north and 1 south. A 4-pole motor has 4 eletromagnets; 2 north and 2 south. On a 4-pole motor, the magnets are set up in a north-south-north-south configuration. Basically, a 2-pole motor is a good RPM motor while a 4-pole motor, having more magnets, will have more torque.

What is a 2 Pole Motor?

A two-pole motor is a type of electric motor that has two magnetic poles in its stator and rotor, making it a simple and commonly used configuration. The two poles refer to the two opposite magnetic poles on either side of the motor. These motors are commonly used in many applications due to their simplicity, efficiency and relatively low cost.

- Construction:

- Stator: The stator is the stationary part of the motor. It consists of a laminated core made of magnetic materials like silicon steel sheets. Winding coils are placed around the stator core to create an electromagnetic field.

- Rotor: The rotor is the rotating part of the motor. It also consists of a laminated core with winding coils. The rotor windings are connected to form closed loops that enable the motor to rotate when a current passes through them.

- Working Principle:

- When an electric current is supplied to the stator winding coils, it creates a magnetic field with two poles: North (N) and South (S).

- This magnetic field induces an electromagnetic force in the rotor winding coils, which causes the rotor to align itself with the stator’s magnetic field.

- As the stator’s magnetic field alternates, the rotor follows the magnetic poles and rotates, completing one revolution for each full cycle of the stator’s alternating current.

What You Need To Know About 2 Pole Motor

- 2 pole motor is a type of motor that has two magnetic poles or a pair of magnetic pole.

- Rotor of the 2 pole motor completes one cycle for every cycle of the source.

- A 2 pole motor shows a north-south configuration.

- 2 pole motor has high speed due to less number of poles.

- 2 pole motor has less workout when compared to a 4 pole motor.

- 2 pole motor has a good noise performance.

- A 2 pole motor is cylindrical in shape.

- A 2 pole motor has more revolution per minute.

- Gearbox below 3000rpm is always required for a 2 pole motor.

- A 2 pole motor has higher NPSHR.

- A 2 pole motor is not suitable for heavy power.

- 2 pole motor is more efficient.

Also Read: Difference Between 4 pole and 6 pole motor

What is a 4 Pole Motor?

A four-pole motor is a type of electric motor that has four magnetic poles in its stator and rotor. It is a widely used configuration that offers improved performance compared to two-pole motors in certain applications. The four poles refer to the four opposite magnetic poles on either side of the motor, resulting in a more complex but versatile motor design.

In other words, 4 pole motor is a type of motor with 4 magnetic poles or two pairs of magnetic poles, with a north-south-north-south configuration. A 4 pole motor consumes more energy, has fewer revolutions per minute, and delivers more torque per horsepower and work output. This type of motor is suitable for heavy power applications.

- Construction:

- Stator: The stator is the stationary part of the motor and consists of a laminated core made of magnetic materials like silicon steel sheets. Winding coils are placed around the stator core to create an electromagnetic field.

- Rotor: The rotor is the rotating part of the motor and also consists of a laminated core with winding coils. The rotor winding coils are connected to form closed loops, enabling the motor to rotate when a current passes through them.

- Working Principle:

- When an electric current is supplied to the stator winding coils, it creates a magnetic field with four poles: North (N) and South (S) on both sides.

- This magnetic field induces an electromagnetic force in the rotor winding coils, causing the rotor to align itself with the stator’s magnetic field.

- As the stator’s magnetic field alternates, the rotor follows the magnetic poles and rotates, completing one revolution for every two cycles of the stator’s alternating current.

What You Need To Know About 4 Pole Motor

- 4 pole motor is a type of motor with 4 magnetic poles or two pairs of magnetic poles.

- 4 pole motor completes only half a cycle for every single cycle of the source.

- A 4 pole motor shows north-south-north-south configuration.

- A 4 pole motor has low speed due to more number of poles.

- 4 pole motor has double work output than a 2-pole motor.

- A 4 pole motor does not have a good noise performance.

- The 4 pole motor is not cylindrical.

- A 4 pole motor has less revolution per minute.

- Generally, there is no need for gearbox in a 4 pole motor.

- The 4 pole motor has low NPSHR.

- 4 pole motor is suitable for heavy power.

- A 4 pole motor is less efficient.

Also Read: Difference Between Stepper Motor And Servo Motor

2 Pole Motors vs 4 Pole Motors In Tabular Form

| BASIS OF COMPARISON | 2 POLE MOTOR | 4 POLE MOTOR |

| Description | 2 pole motor is a type of motor that has two magnetic poles or a pair of magnetic pole. | 4 pole motor is a type of motor with 4 magnetic poles or two pairs of magnetic poles. |

| Number Of Cycle For Every Cycle Of The Resource | Rotor of the 2 pole motor completes one cycle for every cycle of the source. | 4 pole motor completes only half a cycle for every single cycle of the source. |

| Configuration | A 2 pole motor shows a north-south configuration. | A 4 pole motor shows north-south-north-south configuration. |

| Speed | 2 pole motor has high speed due to less number of poles. | A 4 pole motor has low speed due to more number of poles. |

| Work Output | 2 pole motor has less workout when compared to a 4 pole motor. | 4 pole motor has double work output than a 2-pole motor. |

| Noise Performance | 2 pole motor has a good noise performance. | A 4 pole motor does not have a good noise performance. |

| Shape | A 2 pole motor is cylindrical in shape. | The 4 pole motor is not cylindrical. |

| RPM | A 2 pole motor has more revolution per minute. | A 4 pole motor has less revolution per minute. |

| Gearbox | Gearbox below 3000rpm is always required for a 2 pole motor. | Generally, there is no need for gearbox in a 4 pole motor. |

| NPSHR | A 2 pole motor has higher NPSHR. | The 4 pole motor has low NPSHR. |

| Suitability | A 2 pole motor is not suitable for heavy power. | 4 pole motor is suitable for heavy power. |

| Efficiency | 2 pole motor is more efficient. | A 4 pole motor is less efficient. |

Also Read: Difference Between Stepper And Servo Motor