When it comes to functioning of various machines, two components are very important in maintaining smooth and efficient operations: the flywheel and the governor. These mechanical devices work different in their respective applications.

The flywheel is a rotating mass that acts as an energy storage reservoir, mainly used to regulate the rotational speed of a machine or system whereas the governor serves as a speed-regulating device that adjusts the energy input to ensure a consistent speed despite changing load conditions.

The speed changes occur due to the following:

- Due to changes of the torque on the crankshaft.

- Due to changes on the load on the engine.

What is a Flywheel?

A flywheel is a mechanical device used to store rotational energy and regulate the speed of a machine or system. It serves as a kinetic energy reservoir, absorbing energy during periods of excess power and releasing it during times of reduced power or increased demand. The name “flywheel” comes from the historical use of these devices in early machines, where they appeared to be wheel-like structures that spun rapidly like a “fly” (a small insect) when set in motion.

The main function of a flywheel is to stabilize the rotational speed of a machine by reducing fluctuations caused by varying loads or intermittent power sources. It achieves this by maintaining its angular momentum, which resists changes in rotational speed. When the machine produces excess power, the flywheel stores the surplus energy as rotational kinetic energy. During periods of increased demand or reduced power generation, the flywheel releases this stored energy to keep the machine’s speed constant.

A flywheel consists of a heavy circular disc or ring-shaped object with a shaft running through its center, allowing it to rotate freely. The material used for constructing flywheels is often chosen for its high density and strength, such as steel, cast iron, or composite materials. The circumference of the flywheel is usually designed to have a high moment of inertia, which is a measure of the object’s resistance to changes in its rotational motion. A higher moment of inertia allows the flywheel to store more energy for a given rotational speed.

Applications of Flywheels

- In internal combustion engines, the flywheel smoothens the power delivery to the crankshaft, reducing vibrations and providing rotational inertia to enable smoother engine operation.

- They are used in industrial machines like metal-cutting machines and textile machinery, to provide stability and regulate rotational speeds.

- They are common in energy storage systems, especially in combination with renewable energy sources like wind and solar power. During periods of excess power production, the energy is stored in the flywheel, and when power demand exceeds supply, the stored energy is converted back to electricity.

- Flywheels are used in certain hybrid and regenerative braking systems to store energy during deceleration and reuse it during acceleration.

Advantages and Limitations

Advantages

- By absorbing and releasing energy, flywheels help in maintaining a constant speed, leading to smoother operation of machines and engines.

- In energy storage applications, flywheels can be highly efficient, providing rapid energy discharge and recharge cycles.

- Flywheels are relatively simple and robust devices, requiring minimal maintenance.

Limitations

- To store significant amounts of energy, flywheels may need to be large and heavy, limiting their use in some applications.

- Flywheels operate at high rotational speeds, which can present safety and engineering challenges, requiring proper containment and control mechanisms.

What is a Governor?

The concept of the governor dates back to the 18th century when James Watt, a Scottish engineer and inventor, developed the centrifugal governor for use in steam engines.

A governor is a speed-regulating device used to control the speed of engines, turbines, and various machines. Its main role is to maintain a constant rotational speed despite changes in the applied load or external factors by controlling the supply of fuel or working fluid of the engine with concurrent variation in load. Governors are crucial in ensuring the smooth and efficient operation of machines, as they help prevent over-speeding or under-speeding.

The governor’s operation relies on a feedback mechanism that compares the actual speed of the machine with a preset desired speed (setpoint). If the actual speed deviates from the setpoint, the governor takes corrective action to adjust the energy input and bring the machine’s speed back to the desired level. The control mechanism often involves adjusting the throttle or fuel supply to the engine.

In other words, when the load increases in the engine, the speed of the engine needs to be decrease by decreasing the supply of fuel (working fluid). When the load in the engine decrease, the speed of the engine need to be increased by increasing fuel supply (working fluid).

Also Read: Difference Between Supercharger And Turbocharger

Types of Governors

There are many types of governors, but the most common ones include:

- Centrifugal Governor: This type of governor operates based on centrifugal force. It consists of a set of revolving masses or weights attached to arms. As the machine’s rotational speed changes, the centrifugal force acting on the weights causes them to move outward or inward, affecting the control mechanism accordingly.

- Inertia Governor: Inertia governors use the principle of inertia to regulate speed. They typically consist of a rotating shaft with two flyweights. When the rotational speed changes, the inertia of the flyweights causes them to move outward or inward, adjusting the machine’s output accordingly.

- Hydraulic Governor: Hydraulic governors use fluid pressure to control speed. They are often used in large steam turbines and other hydraulic systems. Changes in rotational speed cause variations in fluid pressure, which then actuates the control mechanism.

- Pneumatic Governor: Pneumatic governors use air pressure variations to regulate speed. They are commonly found in air compressors and pneumatic systems.

Applications of Governors

- In steam engines and turbines, governors regulate the steam flow and fuel supply to maintain a constant rotational speed, ensuring stable operation and preventing damage due to overspeeding.

- In power generation systems, governors regulate the output of generators to match the electrical demand and maintain grid stability.

- Though modern cars use electronic engine control systems, governors are still used in specific applications, such as industrial and marine engines.

- In industrial machines, such as centrifugal pumps, fans and compressors also use governors to control their speed and optimize their functionality.

Advantages and Limitations

Advantages

- By maintaining a constant speed, governors ensure stable and reliable operation of machines, preventing mechanical failures and accelerating efficiency.

- Governors help distribute the load evenly among multiple machines and thus minimizing wear and tear.

Limitations

- Some types of governors may have limitations in responding quickly to sudden changes in load, which can lead to temporary speed fluctuations.

- Advanced governors can be complex, requiring careful design and calibration to work as per their expectation.

Key Difference

- Function:

- A flywheel is a rotating mechanical device used to store rotational energy, acting as a kinetic energy reservoir. It helps in maintaining the rotational speed of a machine or system by absorbing and releasing energy as needed.

- A governor is a speed regulating device that controls the speed of an engine or machine by adjusting the fuel or energy input based on the load changes. It helps to maintain a constant speed under varying conditions.

- Purpose:

- The primary purpose of a flywheel is to provide rotational inertia, which helps to smooth out fluctuations in rotational speed and prevent sudden speed changes.

- The primary purpose of a governor is to keep the rotational speed of an engine or machine constant despite changes in the applied load.

- Application:

- Flywheels are commonly used in engines, machinery, vehicles, and energy storage systems like flywheel batteries.

- Governors are primarily used in engines, turbines, and various machines where a constant speed is essential for their efficient operation.

- Operation:

- A flywheel stores energy in the form of rotational kinetic energy and releases it to compensate for speed variations.

- A governor senses the rotational speed of the engine or machine and adjusts the throttle or fuel input to control the speed.

- Physical structure:

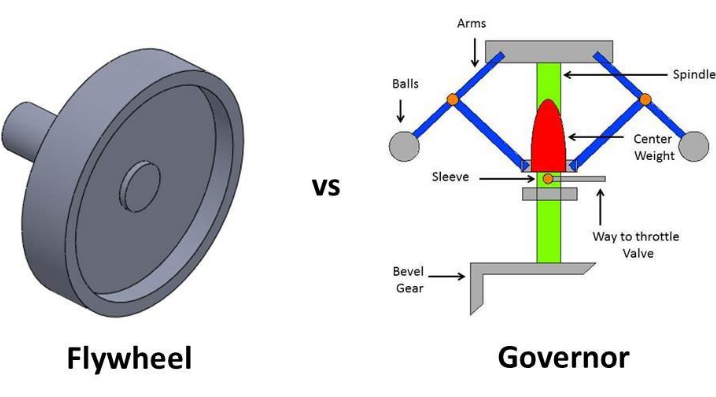

- A flywheel is a solid disc or ring-shaped object with a large moment of inertia.

- A governor typically consists of revolving masses or weights attached to arms, levers, and a linkage mechanism.

- Control mechanism:

- Flywheels do not have a control mechanism. They store and release energy passively based on the system’s requirements.

- Governors have an active control mechanism that continuously adjusts the throttle or fuel supply to maintain a constant speed.

- Speed range:

- Flywheels are effective in stabilizing speed fluctuations over a short range, but they do not actively control the speed.

- Governors are designed to regulate and maintain a constant speed over a wide range of load variations.

- Energy storage:

- Flywheels store energy in the form of rotational kinetic energy.

- Governors do not store energy; their function is solely to regulate the speed in real-time.

Also Read: Difference Between Diesel And Petrol Engine

Difference Between Flywheel and Governor In Tabular Form

| BASIS OF COMPARISON | FLYWHEEL | GOVERNOR |

| Description | A flywheel is a mechanical device specifically designed and attached to the crank shaft so as to control the fluctuations of speed during different rotational operations. | A governor is a mechanical device used to govern the speed of machines. It allows the engine to run at the selected speed without any effect of changing the load. |

| Influence on Speed | Flywheel controls the variation of speed in each cycle of the operating engine. | Governor controls the mean speed only when load varies or when it’s required by controlling the fuel supply to the engine. |

| Weight | Flywheel is a heavy machine component, though it cannot change the speed of the crankshaft. | Governor is relatively light machine component used to limit engine speed. |

| Main Function | Flywheel stores the energy during the power stroke when requirement is less and transfer to shaft when it is required during other strokes of engine. | Governor on the other hand, works only to keep the mean speed of running machine constant by regulating the fuel supply. When the load increases the fuel supply increases by opening of the throttle. The reverse is also true. |

| Condition | The flywheel may not be used if the cyclic fluctuations of energy output are small or negligible (insignificant). | Governor is essential for all types of engines to adjust the fuel supply as per the demand. |

| Mandatory | Flywheel is mandatory for the machines like bikes for the start of operation. | Governor is mandatory for devices where constant speed is desired like in generator. |

| Moments of inertia | Flywheel has large moments of inertia because of the heavy mass of the rotating wheel. The wheel is usually made up of high density cast iron. | The governor has relatively less moments of inertia when compared to flywheel. |

| Under Operation | The flywheel is under operation when the engine is running because it is attached to the crankshaft. | The governor is under operation only when the engine is not running at its mean speed. |

| Extra Mechanism | Flywheel does not need any extra mechanism to supply back energy. | Governor needs a piston (plunger) mechanism. |

| Size | The size of flywheel may differ from one machine type to another. | Governors come in different variety to be used in different prime movers. |

| Energy Storage | Flywheel is an energy storing device and prevents the changes in energy during each cycle of engine operation. | Governor is not an energy storing component. |

| Connection | Flywheel is connected to the crank shaft and runs it at a constant speed, both the flywheel and crankshaft rotates simultaneously. | The governor is not connected to the crankshaft; it can sometimes be electronically operated. |

| Valves | Flywheel does not have valves attached to it. | Governor has valves whose opening is controlled by the centrifugal force on the balls attached to it. |

| Application | Flywheel is used in IC engines of automobiles, punching press and rolling mills etc. | Governor is used in machines where constant speed needs to be maintained such as turbines and generators. |

| Classification | Governor is mainly classified as per the working principle e.g centrifugal type and inertia type governor. | Flywheels are mainly classified as per their size and shape e.g Rim type, Disc type and split flywheel. |