A beam is a very important component of construction or building. However, every steel or metal beam is not the same; rather they are distinguishable from each other in terms of grade, size, shape and even quality of metals used in its making. Some of the common forms of beams include:

- Universal Beams

- W-Beam

- H-beam

- I-Beam

- Rolled Steel Joist

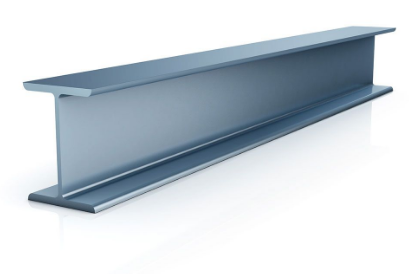

What Are I-beams?

The I-beam consists of two horizontal planes referred to as flanges, connected by one vertical component or the web. The shape of the flanges and the web create an “I” cross-section. The inner surface of the upper and lower flanges of the I-beam has a slope, which makes the flanges thin outside and thick inside. I-beams come in a variety of weights, section, depth, flange widths, web thickness and other specifications for different purposes.

The I-shaped cross-section steel beams come in two different styles; one has a parallel flange surface (wide), whereas the other one has a slope on the inner flange surfaces.

Most I-beams are made from steel whereas others are made from aluminum. The structure and design of the I-beam makes them uniquely capable of handling a variety of loads. They are capable of bending under high stress instead of buckling. In this regard, they are used for building steal bridges and buildings, building support frames for trolleys ways, hoists and lifts.

Other applications of I-beams

- Support beams for construction, facilities and engineering

- Support steel channels, steel angles

- Workplace platforms

- Factory and warehouse

- Truck bed framing

What You Need To Know About I-Beam

- An I-beam usually has a thinner center web, which means it is often not able to take as much force as H-beam.

- An I-beam is not fabricated by welding or riveting sheets of metal together; I-beams are often milled or rolled, it is just one piece of metal throughout. I-beams have top and bottom flanges and they are shorter and are not as wide as H-beams.

- I-beam has tapered flanges for increased strength and a good load bearing capacity under direct pressure.

- The cross section of an I-beam can bear direct load and tensile stress but cannot resist twisting because their cross section is very narrow.

- I-beam is used for steal bridges and buildings and support frames for trolleys ways, hoists and lifts.

- An I-beam may be used for spans of between 33 and 100 feet. Longer I-beams are not often an option since there manufacturing process is quite involving due to their complex shape and dimensions.

- I-beams are lighter when compared to H-beam.

- The I-beam is fabricated by milling or rolling the steel.

- The flanges on an I-beam are shorter and not as wide.

- The distance from the end of the flange to the center web is shorter on an I-beam than the same measurement on an H-beam flange.

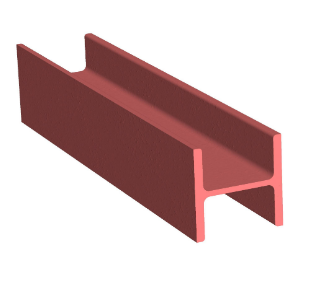

What Are H-beams?

H-beam is a structural beam with H-shaped cross section made of rolled steel. H-beam is a widely used steel beams in structure buildings. The flanges of H-beam steel are all of equal thickness, with rolling sections. They are also wide and the inner and outer surfaces are usually parallel, which makes them strong in connecting high-strength bolts and other components.

The web and flanges of H-beam have what is referred to as a bevel, where three pieces of metal come to join and in the end appear like one piece of metal. H-beams have top and bottom flanges that stick out further from the web than the flanges on I-beams. H-beam is ideal for mezzanines, bridges and platforms and for other residential building projects.

The primary difference between H-beams and I-beams is that the H-beams have thicker walls and flanges, a factor that makes them more ideal for the construction of platforms of varying sizes. The thicker flanges make H-beams stronger and able to support larger amounts of weight.

Other Applications Of H-Beams

- Construction of skyscrapers

- Construction of giant industrial complexes.

- Construction of frames for trolley ways, elevators, trailers and even truck bed

What You Need To Know About H-beam

- An H-beam has a significantly thicker web and thus it is often stronger.

- The web and flanges of H-beam have what is referred to as a bevel, where three pieces of metal come to join and in the end appear like one piece of metal.

- H-beams have top and bottom flanges that stick out further from the web than the flanges on I-beams.

- The cross section of an H-beam can bear direct load and tensile stress; and can resist twisting because their cross section is very wide.

- H-beam is ideal for mezzanines, bridges and platforms and for other residential building projects.

- H-beams can be built up to any size or height. It can be used for spans up to 330 feet.

- H-beams are heavier than I-beams.

- H-beams are built up rather than milled.

- The flanges on an H-beam are longer and stick out further from the center web.

- The distance from the end of the flange to the center web is longer on an H-beam than the same measurement on an I-beam flange.

Also Read:Difference Between Beam And Column

Difference Between I-Beam And H-Beam Steel In Tabular Form

| BASIS OF COMPARISON | I-BEAM | H-BEAM |

| Description | An I-beam usually has a thinner center web, which means it is often not able to take as much force as H-beam. | An H-beam has a significantly thicker web and thus it is often stronger. |

| Bevel | An I-beam is not fabricated by welding or riveting sheets of metal together; I-beams are often milled or rolled, it is just one piece of metal throughout. I-beams have top and bottom flanges and they are shorter and are not as wide as H-beams. | The web and flanges of H-beam have what is referred to as a bevel, where three pieces of metal come to join and in the end appear like one piece of metal. |

| Flanges | I-beam has tapered flanges for increased strength and a good load bearing capacity under direct pressure. | H-beams have top and bottom flanges that stick out further from the web than the flanges on I-beams. |

| Cross Section | The cross section of an I-beam can bear direct load and tensile but cannot resist twisting because their cross section is very narrow. | The cross section of an H-beam can bear direct load and tensile stress; and can resist twisting because their cross section is very wide. |

| Application | I-beam is used for steal bridges and buildings and support frames for trolleys ways, hoists and lifts. | H-beam is ideal for mezzanines, bridges and platforms and for other residential building projects. |

| Spans | An I-beam may be used for spans of between 33 and 100 feet. Longer I-beams are not often an option since there manufacturing process is quite involving due to their complex shape and dimensions. | H-beams can be built up to any size or height. It can be used for spans up to 330 feet. |

| Weight | I-beams are lighter when compared to H-beam. | H-beams are heavier than I-beams. |

| Fabrication | The I-beam is fabricated by milling or rolling the steel. | H-beams are built up rather than milled. |

| Flanges | The flanges on an I-beam are shorter and not as wide. | The flanges on an H-beam are longer and stick out further from the center web. |

| The Distance From The End Of The Flange To The Center Web | The distance from the end of the flange to the center web is shorter on an I-beam than the same measurement on an H-beam flange. | The distance from the end of the flange to the center web is longer on an H-beam than the same measurement on an I-beam flange. |

Also Read: Difference Between One-way And Two-way Slab

Comments are closed.